Blog

The choice between CO2 and fiber laser technology for your specific application depends on various factors, including the material you're working with, the thickness of the material, the desired weld quality, production volume, budget, and more.... View More>>

Plasma cutting machines and fiber laser cutting machines are two distinct technologies used in the metal fabrication industry. Let's compare these two types based on various factors.... View More>>

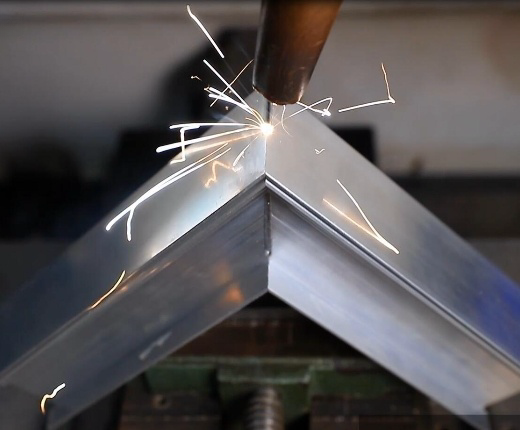

Fiber lasers have gained popularity for welding applications due to their unique advantages, which make them a preferred choice for many industries.... View More>>

Many manufacturers are increasingly switching to welding with fiber lasers from traditional welding techniques for several compelling reasons... View More>>

Operating a fiber laser cutting or welding machine involves several safety precautions to protect personnel, maintain equipment integrity, and ensure the safe operation of the laser system. Here are some essential precautions to take when working with fib... View More>>

Daily maintenance of a fiber laser cutting machine is essential to ensure its optimal performance and longevity. Here are some steps and tips for conducting daily maintenance... View More>>

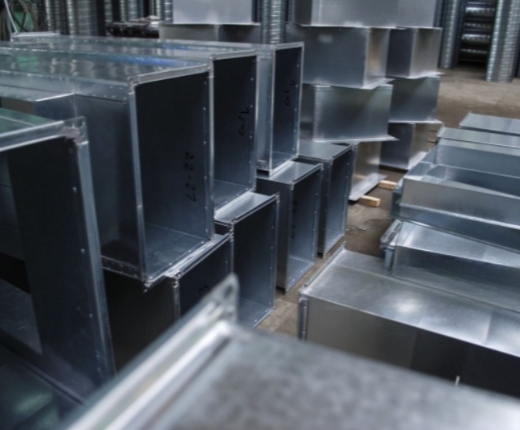

Metal fiber laser cutting and welding machines are versatile tools that find a wide range of applications in various industries. Here are some specific applications for these machines:... View More>>

Avoiding machine downtime is crucial for maintaining productivity and efficiency in any manufacturing operation. Here are some strategies to help minimize machine downtime.... View More>>

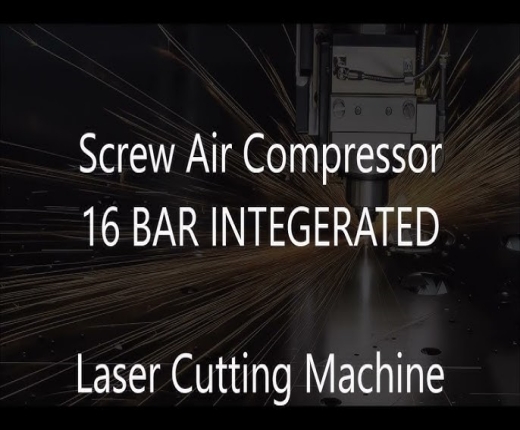

The air compressor and compressed air system needed for a laser cutting machine, such as a fiber laser cutting machine, play a crucial role in ensuring the efficient operation of the equipment. The specific requirements can vary depending on the laser sys... View More>>

Total: 9

Page: 1 / 1

First

←Previous

Next→

End

GUANGDONG LISHI LASER TECHNOLOGY CO., LTD.

GUANGDONG LISHI LASER TECHNOLOGY CO., LTD.